Vulcan : Automated Hot Block

Vulcan is the first automated workstation combining the two essential steps of sample preparation -Digestion and Work-up. It is the only true automation accepting samples and returns prepared autosampler racks ready to be analysed.

Offers:

- Freedom from manual acid handling and exposure to acid fumes

- Substantial cost savings in sample analysis expenditure

- Contamination free environment for trace level sample preparation.

- Overcomes inconsistencies and uncertainties introduced by repetitive and tedious process.

- Increase in laboratory throughput.

- Saves prime lab space with smart inbuilt fume hood.

- Documentation of sample preparation processes

- Effective use of skilled manpower through unattended operations

- Provides safe and healthy work environment

- Processing of 84 samples in 50 ml vials.

- Automatic and precise addition of corrosive acids, reagents and internal standard.

- Multistep heating of hot blocks.

- Makeup volume at the end of digestion.

- Stirring of sample during the process.

- Cooling digestion vials between reagent additions.

- Transferring and diluting samples to autosampler racks

- Can handle two digestion recipes at same time

Heating (Hot Blocks):

- Capable of heating up to 400º C.

- Hot blocks available to accommodate 15, 25, 50 and 100 ml digestion vials

- Vilas available in Teflon, Glass and Polypropylene material.

- Customise hot block available to accept specific size and shape of digestion vessel.

- Teflon® coated graphite block and housing to prevent contamination.

- Anodised Aluminum Block for higher temperature applications

- Choice of All-plastic housing for extreme corrosion resistance

- Unparalleled Temperature homogeneity of 1.50 C across the block

Post Digestion Sample Work-up:

Makeup Volume:

Sample levels are monitored for individual vials using non contact level sensor. Peristaltic pump fills in quickly major amount for desired level. Accurate Syringe pump dispensing and level sensor monitoring is used in achieving final level. This unique combination of syringe and peristaltic pump helps speed up process with out losing accuracy.

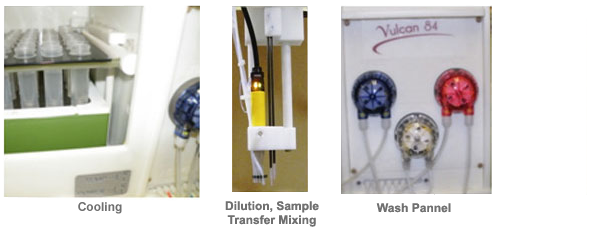

Dilutions and Sample Transfer:

With the help of Teflon coated Carbon Fibre probe and Sample loop samples are picked up, stored, diluted and transferred to autosampler racks. Sample Probe and Loop is thoroughly cleaned externally and internally between each sample processing. It is possible to generate multiple dilutions for one sample in one go.

Cooling:

Pneumatically driven acid resistant Tray Lift brings samples out of hot blocks. Tray Lift is placement forces cool air to pass over the vials, bring them rapidly to room temperature for multiple reagent additions and Volume Make-up.

Stirring:

Vigorous mixing of sample is effected through rapid stream of air bubbles. Duration of mixing for each sample can be set as per need.

Wash Station:

Two Chambered wash station is used for cleaning the probes between two sample. Wash station has two separate peristaltic pumps circulating clean water for efficient cleaning.

Dispensing Reagents

- Accurate and consistent reagent delivery for acids and reagents through dedicated lines.

- Capable of handling corrosive acids like HF, H2SO4 and HClO4.

- Deliver reagents and acids as required by each sample in a single run, thus can handle multiple types of samples at one time

- Can configured to dispense reagents in multiple vials to increase the speed.

- 6 individually operated syringes

- Teflon syringe to handle HF acid

- All Teflon values and fittings to provide inert environment

- Programmed to dispense precise amounts from 6 syringes at same time

- Designed for ease of mounting and replacement

- 8 individually operated pumps

- Accurate delivery over wide range of flow rate

- Specialised design to provide Low drift in the flow rate

- Gentle pulsing to provide steady flow and accurate control on volume

- Good repeatability in low volume dispensing

- Operate in dispense and aspirate mode to facilitate sample pickup and avoid reagent dripping

- Manual switch to prime the pump

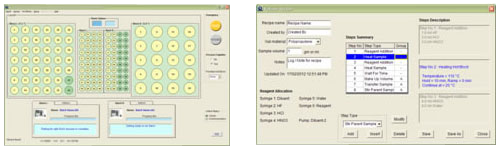

Diligent Software Control

- Easy-to-build digestion recipe with functional steps like reagent addition, heating, stirring, sample transfer, washing and autosampler rack preparation.

- Offers unique functionalities like Heat to Dryness and Precipitate / Residue washing.

- Easy-to-set automation functions resulting in quick optimisation of the whole process.

- Capable of altering processing for individual vial in single run.

- Allows running of different digestion recipes at same time on each block

- Easy-to-configure variety of hot block and sample rack configurations

- Accepts rush, urgent or stat samples during the run

- Accepts changes in processing parameters in the run

- Capable of continuing process after break

- Estimates and displays digestion process time and progress

- Prompts when reagent bottles need replacement

- Process documentation capability

All Plastic Housing

- Saves prime lab space with smart inbuilt fume hood

- Perchloric-acid-Ready, detachable exhaust manifold to facilitate washing.

- No metal parts, all plastic construction suitable for trace level sample preparation.

- Laminar flow exhaust path for acid fume removal.

- Positive air pressure in electronic section prevents acid corrosion.

- Option of HEPA filter attachment.

- Provides catchment basin for any reagent spillage.

- Has transparent window for light illumination and visual observation.